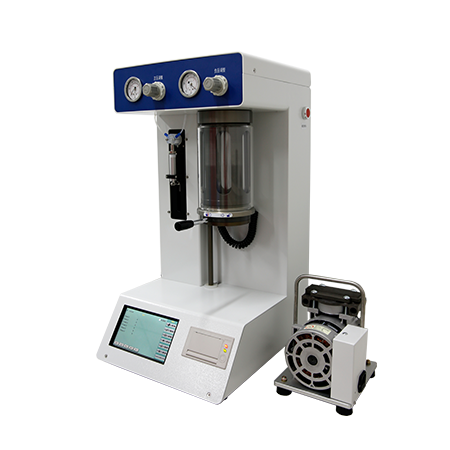

KN-4406 Oil Liquid Particle Counter

Overview

KN-4406 Oil Liquid Particle Counter is a laboratory Instrument used to detect particle contaminants in liquids. It uses the principle of light blocking to detect and count the size of particles in liquids, thereby calculating the distribution and pollution situation of particles. The Instrument is equipped with pressurized and vacuum devices, which can effectively extract high viscosity detection liquids and eliminate microbubbles in liquids and is widely used for the detection of particle contaminants in liquid medium such as hydraulic oil, lubricating oil, transformer insulation oil, gear oil, aviation kerosene, organic liquid or polymer solution.

Features

1. Adopts the photoresist (shading) method counting principle formulated by the International Hydraulic Standards Committee

2. High-precision laser sensor, it features wide test range, stable performance, low noise and high resolution

3. Adopts high-pressure syringe pump sampling method, the sampling volume can be set by actual demands, the injection speed is stable, and the sampling accuracy is high

4. The combination of positive and negative pressure injection system is able to do sample degassing, which is suitable for testing samples with different viscosities

5. Built-in pressure sensor, which can directly set the pressure value and automatically judge the air pressure in the chamber to ensure safety

6. The main host has a built-in air purification system to ensure that the test will not be polluted, with a high degree of integration, and to avoid secondary pollution caused by the air tightness of the air pump and the test system

7. Built-in multiple calibration curves, which can be compatible with all commonly used standards

8. Built-in GJB-420A, GJB-420B, NAS1638, GB/T14039, ISO4406, SAE4059cpc, SAE4059F, SAE749D, ГOCT17216, QC/T29104, JB/T9737, DLT432, HH005-2018, etc.

9. Customized test method is available, which can be named and do the grade judgement

10. Base on the demands, be able to set maximum 64 test channels simultaneously

11. Be able to do cleaning detection, the target cleaning requirement particle concentration can be set in advance, the cleaning status can be displayed in real time during the cleaning process, and it will automatically stop when the requirements are reached

12. Built-in viscosity, moisture and temperature sensor module provides viscosity, moisture content saturation and ppm value and temperature reference value while accurately measuring particle distribution (optional)

13. The particle size can be set arbitrarily, and nearly 10,000 particle sizes are built-in, which is convenient for particle size analysis

14. A variety of sampling containers such as standard sampling bottles or sampling cups can be used to meet the requirements of different fields

15. Full-featured 7-inch color touch screen operation, folding button design, simple and convenient operation

16. Manual, automatic, and half-count calibrations are available

17. Equipped with RS232 port, supports 485 communication, be able to connect to connect to PC or laboratory platform for data processing

18. Massive data storage capacity and be able to print the test results, and can save the data into USB flash disk. Saved data can be output to flask disk directly

19. Be able to set up more than 5 accounts, and the operator permissions can be set separately

Technical specification

1. Light source: semiconductor laser

2. Particle size range: 0.8μm~600μm (calibrated according to ACFTD calibration 1~100μm or ISO MTD calibration 4~70μm(c))

3. Detection channel: 8~64 channels optional (default 64 channels), be able to set any particle sizes

4. Sensitivity: 0.8μm (ISO4402) or 3μm (c) (ISO11171)

5. Resolution: <10% (GB/T18854, ISO11171)

6. Repeatability: RSD<2%

7. Viscosity of sample: ≤650cSt (excessive viscosity can be detected by heating or dilution method)

8. Sampling volume: 0.2~6000mL, interval 0.1mL

9. Sampling accuracy: better than ±0.5%

10. Sampling speed: 5 ~80mL/min

11. Chamber: positive and negative chamber to achieve sample degassing and high viscosity sample detection

12. Maximum vacuum of chamber: -0.08Mpa

13. Maximum positive pressure in the chamber: 0.8Mpa

14. Maximum particle concentration: 12000~40000 particles/mL

15. Temperature (paid optional): Range: 1~100°C, accuracy: 1°C

16. Water activity (paid optional): Range: 1~100%RH, accuracy: 1%RH

17. Water content (paid optional): Range: 1~360ppm, accuracy: 1ppm

18. Detection sample temperature range: 0°C~80°C

19. Working temperature: -20°C~60°C

20. Storage temperature: -30°C~80°C

21. Power supply: 110~245V AC, 50/60Hz, 70W

22. Main host dimension: 340mm× 410mm×650mm

23. Air pump size: 180mm× 160mm×220mm

24. Net weight of main host: ≯23kg Net weight of air pump: ≯5.5kg