KN-2409 GC for Glycol Impurities in Mono-, Di-, Tri- and Tetraethylene Glycol

Overview

KN-2409 GC for Determination Glycol Impurities in Mono-, Di-, Tri- and Tetraethylene Glycol. A gas Chromatograph determines the glycol impurities in Mono-, Di- Tri- and Tetraethylene Glycol (MEG, DEG, TEG and TeEG) in the range of 5 to 3000 mg/kg.

Summary

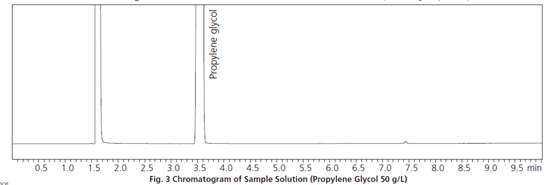

A sample s o l u t i o n was prepared by mixing approximately 5 g of commercially available propylene glycol in 100 mL of methanol. The chromatogram obtained using a 1 μL injection is shown in Fig. 3. Supplement Ⅱ also specifies as follows: The amounts of ethylene glycol and diethylene glycol present in a sample solution are not to exceed 0.1 % respectively based on the standard solution area values. Following elution of the solvent, the area values are to be measured over a range about three times the retention time of propylene glycol. The peak areas of peaks other than propylene glycol, ethylene glycol and diethylene glycol in the sample solution must be no greater than 0.1 %, respectively, calculated by the area percentage method, and the total peak area of all peaks other than propylene glycol must be no greater than 1.0 %.

Features

1. Adopts imported 10.2 inch (1280X800) color touch screen

2. 8 channels control the temperature, 8 external events

3. Be able to set flow rate, pressure, temperature and detector parameters on the PC (Function depends on the exact model)

4. Logarithmic amplifier, no flat solvent peak

5. Screen real-time spectrum display, be able to display three-channel spectrum simultaneously

6. FID automatic ignition

7. 8 channels temperature control, if any channel overtemperature, the system will stop heating and alarm automatically

8. Program heating: 8 steps, be able to do infinite steps heating via programming

9. Every flow rate can be displayed on the screen, no need the pointer pressure gauge

10. At lease3 detectors signal acquisition simultaneously

11. Hydrogen leak protection and carrier gas saving mode: The tester will automatically enter the low-split mode after the injection, which greatly reduces the consumption of carrier gas and operating cost

12. Only one cable can control the tester and data signal output

13. Advanced EPC system, maximum 12 channel electric flow control modules are available

14. Be able to set the related parameters via the workstation

15. Two-way communication between screen and counter control workstation

16. Adopts imported EPC module

Specification

Method | ASTM E2409 |

Channel | 1 |

Sample type | Liquid |

Detection | FID |

Detection limit | 0.5ppm |

Working range | 0.50~100mg./kg |

Sample limitation | Matrix bp<200℃ |

Temperature controlling range | +5~400℃, increment 0.1℃ |

Programming temperature rising | 8 stages rate 0.1-40℃ |

Communication port | Ethernet |

Dimension | 555*525*485mm |

Peak identification

1. monoethylene glycol

2. diethylene glycol

3. triethylene glycol

4. tetraethylene glycol

Chromatogram

FIG, 3

Configuration

No. | Name | Specification | Qty |

1 |

KN-2409 GC for Glycol Impurities in Mono-, Di-, Tri- and Tetraethylene Glycol | 1. 10.2-inch color touch screen, power-on self-check, wide-range self-diagnosis function, intelligent fuzzy control back door system, real-time spectrum display on the screen, 8-step program heating, and infinite-step program heating can be realized by programming. FID automatic ignition function 2. KN-2409 GC system 3. Instant Connect Flame Ionization Detector (FID) Module 4. Capillary column sampling port

| 1 set |

5. EPC module control 9. Carrier gas EPC module control 10. Imported EPC module, the accuracy can reach 0.01psi | 4 sets | ||

2 | Counter control workstation | 1. Be able to set the related parameters on the workstation for all counter control work 2. Ethernet communication interface, a network cable can realize instrument control and signal acquisition and output network control program, anti-logarithmic operation | 1 set |

2 | Air generator | 1. Air purity: Grade 3, without oil 2. Output flow rate:0-3L/min 3. Input pressure: 0-0.4MPa (Adjustable) 4. Rated power:150W | 1 set |

3 | Hydrogen generator | 1. Hydrogen purity: 99.999 2. Output flow rate: 0-300/min 3. Input pressure: 0-0.4MPa 4. Rated power: < 150W | 1 set |

4 | Liquid auto sampler | 24 stations | 1 set |

5 | Capillary column 1 | Spec: 15m*0.53mm1um Analyze: Glycol Impurities in Mono-, Di-, Tri- and Tetraethylene Glycol | 1 pc |